Ceramic Fiber is a lightweight refractory material and its products are widely used in high-temperature areas like furnaces, Kilns, boilers etc. This is a great insulator that has the ability to perform well in high temperature as well as low temperature. The main chemical ingredient of Ceramic fiber is Aluminum Silicate. It is very useful in various industrial products.

Several Products of Ceramic Fiber:

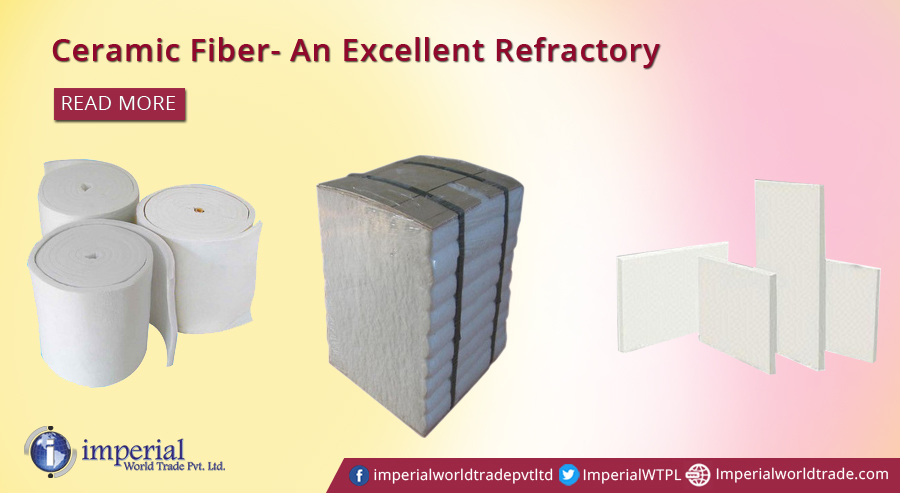

1. Ceramic Fiber Blankets: These Blankets are made of high strength spun ceramic fibers that are useful in high-heat production and thermal management application in several industries. These blankets are available in various densities, widths, thicknesses as per your requirement and can absorb heat up to 3000°F (1650°C).

Features of Ceramic Fiber Blankets:

- – Lightweight

- – Thermal Shock Resistance

- – Less heat Storage

- – Chemical and Corrosion resistance

- – Excellent strength and handling

- – High-temperature stability

Industrial Usage:

- – Fire protective insulation and lining

- – Usage in Kilns, furnaces, boilers, and ovens

- – Expansion joint seal and insulation

2. Ceramic Fiber Modules: These are made of high-quality ceramic fiber blankets compressed and folded together into certain dimensions. This can be quickly installed in high-temperature It is further compressed during installation to provide more strength.

Features of Ceramic Fiber Modules:

- – Fast and easy to install.

- – Available in different sizes as per requirement.

- – Provides faster Insulation.

- – Superior Thermal stability and shock proof.

- – Resistant to mechanical damage.

- – Very less heat storage and lightweight.

- – Can be cut in various sizes during installation.

Industrial Usage:

- – Usage in the Ceramic industry – kilns, Door & Furnace linings, Glazing etc.

- – Power Generation Industry – Heat recovery, Steam System, Stack Linings, Boiler Insulation etc.

- – Steel Industry – Heat treats furnace, Heaters, and reformer lining Soaking pit covers and seals.

3. Ceramic Fiber Boards: Ceramic Fiber Board is refractory fiber board that is vacuum These boards have high resistance qualities and can resist higher gas velocities than Fiber Blankets. It contains low thermal conductivity and low heat storage.

Features of Ceramic Fiber Boards:

- – Easy to install, cutting and handling are

- – Superb Thermal Shock resistance.

- – Good resistance to chemical attacks and gas erosion.

- – These are lightweight with heavy backup

Industrial Usage:

- – Refractory lining for furnaces in roofs, walls, stacks etc.

- – Brick and monolithic factories.

- – Boilers, Heaters and Chamber liners.

4. Ceramic Fiber Paper: This is another excellent and light in weight refractory material. This is made from blending of Almunia-silica fibers into a flexible and uniform sheet.

Features of Ceramic Fiber Paper:

- – Cutting and Wrapping is easy.

- – Low Thermal Conductivity and Heat Storage.

- – Light weight and good dielectric strength.

Industrial Usage:

- – Consumable Insulator for one-time use.

- – Electrical and Thermal Insulation.

- – Gaskets and seals.

- – Casting mold wrap Insulation.