Insulation Bricks

Insulation Bricks

Insulation bricks are made up of the chemical composition of different kinds of insulation materials which help in maximize the conservation of heat and reduced its losses within a furnace. Due to its high porosity and low thermal conductivity, these bricks absorb less heat.

Imperial world trade is well-known name as insulation bricks manufacturer. We are insulation bricks suppliers as well as insulation bricks exporters which export these in USA, UK, UAE and Nigeria. We manufacture all different kinds of insulation bricks.

Usage of Insulation bricks

The usage of insulation bricks can only be categorized on the base of material to use to make it. Let's discuss usage of these insulation bricks

- Fireclay insulation

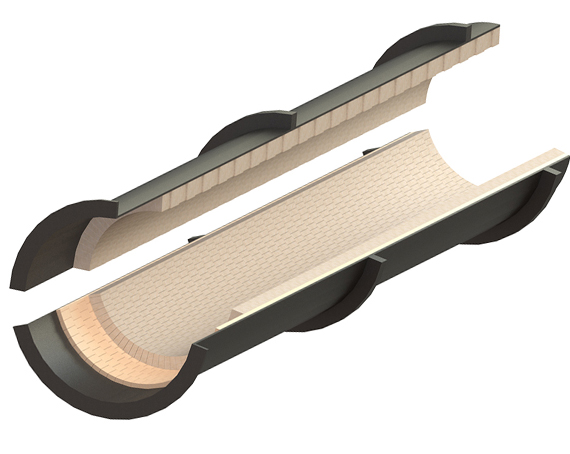

This is a kind of insulation material mainly used in industries. These are used in large furnaces to save energy, reduce heat loss and reduces the load of equipment.

We manufacture it from local top grade fireclay material. Low impurity, low thermal conductivity, high strength, bulk density, etc. are the features owned by these fireclay insulation bricks.

- Silica insulation bricks

These bricks are made up of the chemical composition of top grade silica. These silica bricks own same features as fireclay like high strength, low impurity, etc. but it has half of the thermal conductivity as compared to the fireclay insulation bricks.

Silica insulation bricks are prepared that is shaping and burning in high temperature, therefore, it has high-temperature resistance too. If we compare it with fireclay, it has better thermal shock resistance than that as it has no shrink at high temperature. As well as it has some more features than fireclay insulation bricks as good thermal insulation effect, high softening point, good acid erosion resistance, etc.

- Alumina insulation bricks

These bricks consist 48% alumina; therefore it is very light in weight and is a new type of insulating material. These bricks are mainly used for industrial purposes like in industrial kilns and furnaces used as an essential refractory component so as to save energy and temperature preservation.

Small thermal conductivity, small volume density, high chemical intensity, good insulation effect and high porosity are few features of these aluminum insulation bricks.

- Diatomite insulation bricks

These insulation bricks are made up of bonding high diatomite with other porous materials. The strength and insulation properties are highly improved in these bricks. These bricks can be made only under license holder's technology.

It's shaping is done by casting then sintering at very high temperature, then it's cutting according to the required size and then polishing. It is used in various thermal equipment for hot blast pipes; and used in reduction cells.

We are insulation bricks manufacturer. We are insulation bricks suppliers as well as insulation bricks exporters.

Importance of insulation bricks

These insulation bricks are widely used in many different areas. These insulation bricks are nowadays being used in gas plant furnaces, boilers, blast furnaces, waste incinerators. These bricks are high in heat resistance, very light in weight, easy to use and handle and abrasion resistant.

We are reputed insulation bricks manufacturers; insulation bricks suppliers as well as insulation bricks exporters. Here, we provide all these types of insulation bricks. We provide very light in weight, easy to handle and maintain as well as high in quality.